Design Features

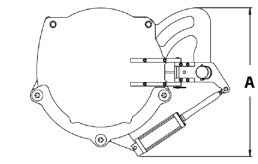

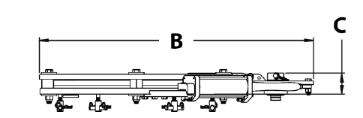

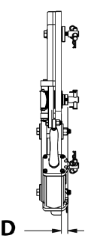

Overall Cover Dimensions:

- A. 29.8″

- B. 40.1″

- C. 3.1″ top of ring to top of cover

- D. 0.9″ top of ring to bottom nut

System Weight:

- Cover and Flange: 92 lbs.

- Pneumatic Cylinder: 6 lbs.

- Control Box: 17 lbs.

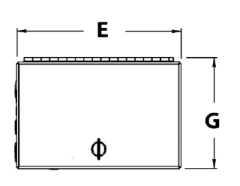

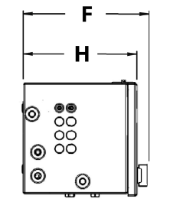

Overall Control Box Dimensions:

- E. 9.7″

- F. 6.9″

- G. 6.5″

- H. 6.3″

- Weather tight seal even when not pressurised

- Lowest profile design, consequently, there is typically no change in the overall height of tanker

- Manufactured from durable machined billet (Type 6061) aluminum for precision and the highest operating pressure ratings

- Food grade seals available

- Lid slides open supported by a HDPE replaceable slide pivoted on non-load bearing hinge pin, thus reducing wear

- A vacuum is applied to the seal when it is deflated, retracting the seal into the lid. This minimises scuffing and wear and extends seal life and reliability

- DOT approved pneumatic fittings

- The scraper and purge functions minimize buildup, reduce maintenance and extend seal life and reliability

- Multiple cover operation from one Control Box, up to 4 hatches on a truck unit can be individually controlled

- Standard operating pressure of 2 bar with units capable of operating at 2.5 bars for rail tankers and specific applications

- Light-weight aluminum construction and bolt on design means you require minimal structural modifications to your tankers

- Flip over lid for ease of maintenance and replacement of seal

- Easy installation to new tankers or can easily be retrofitted to existing vehicle. Installation only takes 3 to 4 man hours using basic tools and components supplied

- Bundled PVC sheathed airlines for ease of installation, providing abrasion and UV protection. Extremely low consumption of compressed air

- Safety Feature – If tanker is opened when pressurized, the seal will deflate and it will be very noisy and dusty. However, until the tanker pressure drops below approx. 5 PSI, and it is safe to open the hatch, the pneumatic cylinder is unable to open the hatch fully

- Optional dust control flange gasket

- Cylinder is not energized when seal is inflated, thereby extending cylinder life